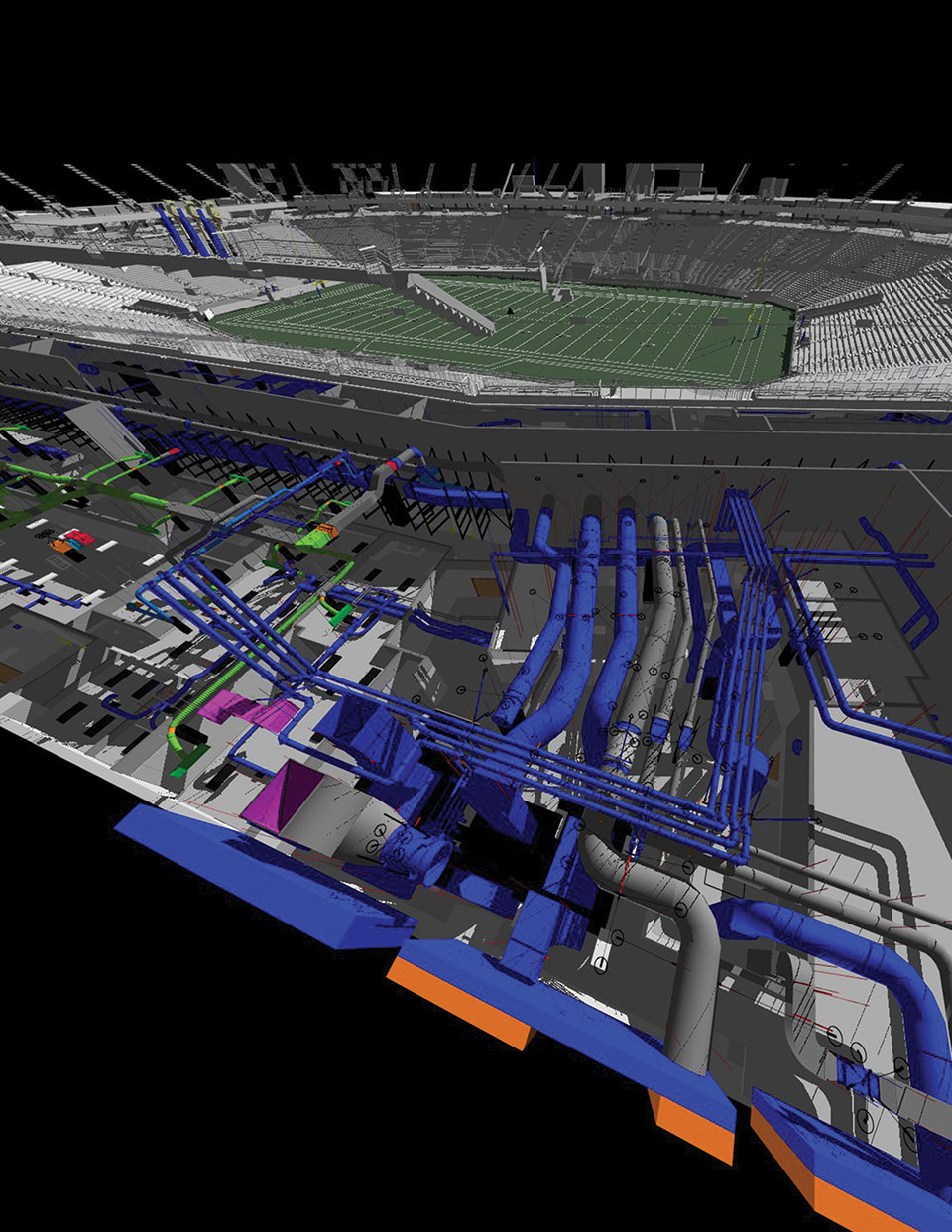

Scanning Capabilities

Scanning & Model/Field Verification for Design & Fabrication

AESI utilizes HD laser scan data of existing piping systems to generate extremely accurate as-built conditions in a virtual environment. The speed and accuracy of laser scanning delivers a point cloud that shows existing conditions accurate to the millimeter in minimal time. Designers use this data to produce a 3-D model to field-verify customer supplied isometrics and to route new piping systems. All modeling designers have extensive piping backgrounds (including field and installation experience), resulting in 3-D models that effectively increase productivity and efficiency in design, fabrication and installation. All orthographic (plan and elevation details) and isometric drawings are legible and produced directly from the 3-D model providing the client cost-effective planning, reduced field time, as well as more accurate and complete data throughout the project.

- Use of laser scanner (data collection)

- In-depth knowledge of project and scan locations

- Scan registration

- Merge scan data into 3-D software to create a comprehensive model

- Field verification of client supplied drawings

- Existing conditions for routing of new piping systems

- Create 3-D model using the latest 3-D software

- Utilize Navisworks for clash detection and model review

- Use 3-D model to create legible orthographic and isometric drawings

- Breaking model into spools for fabrication and installation

- Complete model BOM (Bill of Materials)